Pest & Crop Newsletter, Entomology Extension, Purdue University

- Black Cutworm Moth Arrival Early with Eye-Opening Numbers

- Weevils Wreaking Widespread Woes

- Black Cutworm Adult Pheromone Trap Report

- Soybean Growers and Consultants: Get Free Access to a Wealth of Crop Management Information Courtesy of the Soybean Checkoff

Black Cutworm Moth Arrival Early with Eye-Opening Numbers - (Christian Krupke and John Obermeyer)

• Black cutworm moth arrival has never been this high, this early.

• Moths are seeking weedy fields to lay their eggs, there are plenty to choose from.

• Seed insecticides and Bt hybrids have historically (last year) been of little help in managing high cutworm populations.

• Foliar insecticides have efficacy limitations, best if applied at the time of need.

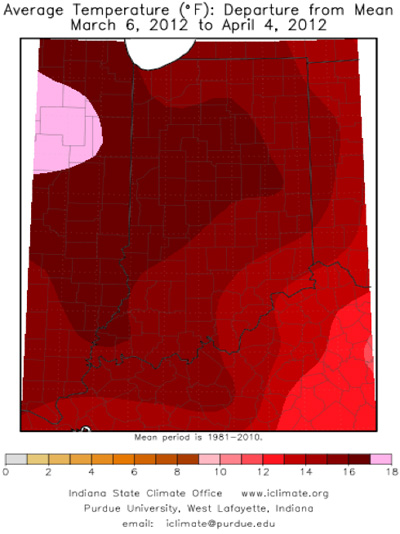

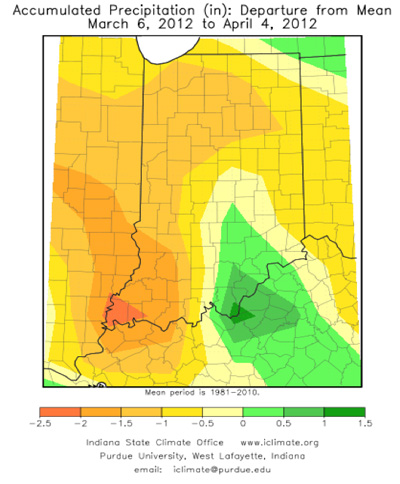

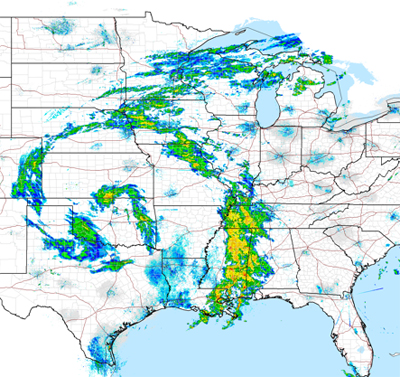

Look at this week’s “Black Cutworm Adult Pheromone Trap Report.” Do it now. Our dutiful cooperators have captured an inordinate number of moths these last couple weeks. We suspect many of those moths were carried here on a large and powerful weather pattern from the southwest that came to Indiana on March 23. Normally we discount these early arriving moths, because they freeze out…not this year. Indiana is the new Georgia and BCW moths are loving it. We’ve begun tracking heat unit accumulations to predict future cutting by this pest, which will be published in future issues of the Pest&Crop.

This rain maker on March 22 likely brought many black cutworm moths into Indiana (NOAA)

What fields will egg-laden black cutworm moths arriving in your area find attractive to lay eggs in? There are some clues that help give us an answer: Barren fields are not appealing. Moths are particularly attracted to winter annuals, such as chickweed and mustards. But the black cutworm has a broad host range, and fields that are showing plenty of green, yellow, and purple (henbit) are at highest risk for cutworm damage. Remember, corn is one of the black cutworm’s least favorite foods, it just so happens it is the only plant remaining by the time larvae have emerged and weeds have been killed. A window of weed-free ground before planting is an ideal solution. Cutworm larvae starve if weeds are treated with tillage or herbicide 2-3 weeks before corn emergence. However, with this season’s compression of field activity, this is unlikely to happen.

Black cutworm moths would have little interest in this lean stubble field for egg laying

After burn-down herbicides, wait at least a week before planting to starve cutworm and/or armyworm larvae

Black cutworm moths would find this field quite appealing for egg deposition

As many producers learned last year with a black cutworm outbreak, seed-applied insecticides do not offer satisfactory control under high pressure. In addition, some varieties of Bt-traited corn do not perform well, those are cases where the label provides only “suppression” and not “control.” Check the fine print on the trait you are using! Weak performance (suppression) is fine under ideal environmental conditions and zero to low-moderate infestation levels. The systemic activity of the seed-applied insecticide, and/or the protein production of the Bt-corn are optimal when the corn seedling is actively growing. However, under environmental stress (i.e., cooler soils) the efficacy of these control products are greatly reduced, leaving the struggling seedling vulnerable to attack by above and below ground insect pests. Admittedly, cooling of soils doesn’t seem likely this spring.

We’ve heard that many fields are being treated with a foliar insecticide at the time of herbicide burn-down. We can understand the proactive approach, especially with such early planting. Understand that these insecticides have their limitations, specifically when subjected to sunlight, rainfall, heat, and dust. Claims of multiple weeks of control with foliar insecticides in spring conditions are simply unfounded; 7-10 days of control is the most optimistic measure. Remember that these are contact insecticides, and as soon as they hit the soil, breakdown begins. Don’t panic - we can manage this pest effectively and have done so in the past: Timely scouting and rescue foliar insecticides when necessary are the tried and true approach with black cutworm. Happy scouting!

![]()

Weevils Wreaking Widespread Woes – (Christian Krupke and John Obermeyer)

• Scout alfalfa NOW!!!

• Warm temperatures have accelerated larval develop-

ment and activity

• Use highest labeled insecticide rate for longest possible residual control

• If a second application is necessary, adhere to product rate restrictions

Alfalfa fields in southern and central Indiana need to be inspected immediately for weevil tip feeding and skeletonization of leaves. Reports from several pest managers have indicated that weevil damage and larval numbers are very high. This is the time to scout and apply insecticides where necessary. Weevils and their damage are very easy to spot, just check the uppermost leaves for damage levels and walk a representative section of the field.

Winter’s mild temperatures have allowed for successful egg and adult over-wintering. Also, based on the numbers and size-variability of larvae, egg laying occurred over an extended period. This means that egg hatch and larval development will be occurring over a longer period than normal. Unfortunately, unless beneficial organisms (both parasitic wasps and pathogenic fungi) begin to really kick into gear, some fields may need to be treated more than once. Should this be the case, be certain to adhere to rate-use restrictions.

Our management guidelines for this time period suggest that fields be treated when there are 3 or more larvae per stem and tip feeding is at least about 50%. Reports from pest managers in the state are showing even higher tip feeding percentages, 100% being quite common. Most insecticide labels suggest using higher rates for increased residual control, we concur with this recommendation.

Severely damaged field by alfalfa weevil, sprayed too late

The sampling procedures for most nematodes are similar. However, samples for the needle nematode must be taken before soil temperatures become too hot, in corn this is usually within 6 weeks after planting. Soil samples must be taken from a depth of 4-6 inches, as close as possible to the infected plants. It is essential to enclose the entire root system with soil surrounding the infected plants. A more detailed sampling procedure can be found on the following website: <http://extension.entm.purdue.edu/nematology/samples.html>.

If you have any questions about corn nematodes or any other kind of plant parasitic nematodes, you can contact Jamal Faghihi at 765-494-5901 or send an email to <jamal@purdue.edu>. Soil samples for nematode analysis can be sent to: Nematology laboratory, Purdue University, Department of Entomology, Smith Hall, 901 W. State Street, West Lafayette, IN 47907-2089. The cost for nematode analysis for each sample remains at $10/sample.

![]()

Click here for the Black Cutworm Adult Pheromone Trap Report

![]()

Wild Garlic Control In No-till Corn And Soybean – (Travis Legleiter and Bill Johnson)

Wild Garlic (Allium vineale) is a weed that has shown up in many Indiana no-till corn and soybean fields this spring. Wild Garlic is most troublesome in wheat, where aerial bulblets contaminate harvested grain and impart the garlic flavor into processed products such as wheat flower. The garlic odor and flavor is also transferred to the milk produced by animals grazing wild garlic. Infestations in corn and soybean fields have less adverse effects on the crop, but can spread quickly across fields and are difficult to control with typical burndown treatments of glyphosate and 2,4-D.

Wild garlic

Wild Garlic ID and Biology

Wild garlic has several distinct characteristics that can make it easily identifiable including the garlic odor it emits when disturbed. It can be readily identified by its smooth linear basal leaves, which emerge from underground bulbs. The basal leaves will be round in cross section and hollow as compared to wild onion that will have solid leaves that are flat in cross section. The bulbs of wild garlic have a papery outer covering and form reproductive bulblets that can be spread with tillage and are capable of remaining dormant for 1 to 5 years.

This perennial weed will emerge from the bulbs in fall or early spring and grow up to 24” in height. Reproductive stems that produce aerial bulblets will emerge in early summer and plants will typically die back shortly after aerial bulblet production. The spread and reproduction of wild garlic is achieved mainly though the aerial and underground bulblets, although on occasion it can reproduce and spread by seed.

Control

Control of wild garlic with herbicides is achievable, although special considerations of its biology need to be taken into account. Herbicide applications need to be made early in the spring when wild garlic is still actively growing and prior to aerial bulblet production. Herbicide options are available for post applications in corn and soybean, but are often considered dismal, as aerial bulblet production and ensuing plant die back usually have begun by this time in the growing season. Burndown applications need to be made with as high of a carrier volume as feasible in order to achieve adequate coverage of the smooth, linear, and erect leaves of wild garlic.

Typical burndown herbicide applications of glyphosate and 2,4-D are variable in controlling wild garlic. Producers wanting to control wild garlic with burndown applications need to include a thifensulfuron and/or chlorimuron-containing product in their burndown program. Products containing thifensulfuron and chlorimuron are listed in Table 1 along with cropping restrictions, application rates, and application comments specific to wild garlic control. These products should be added to existing burndown programs of glyphosate and/or 2,4-D to achieve control of all weed species present as well as wild garlic; some products require the addition of 2,4-D for complete wild garlic control. Producers experiencing high infestations of wild garlic should use high rates of the Harmony products to achieve optimal wild garlic control.

Sources:

R.H. Uva, J.C. Neal, and J.M. DiTomaso. 1997. Weeds of the Northeast. Cornell University Press, Ithica and London. Pg 30

Loux, M.M., et al. 2012. Weed Control Guide for Ohio and Indiana. Ohio State University Extension bulletin 789, Purdue Extension publication WS-16-W.

University of Kentucky Cooperative Extension Service. 2011. Weed Control Recommendations for Kentucky Grain Crops. University of Kentucky Cooperative Extension publication AGR-6.

| Table 1. Herbicides containing the active ingredients chlorimuron and/or thifensulfuron for increased burndown control of wild garlic in no-till corn and soybean fields | |||||

| Trade Name | Active Ingredients | Application Timing and Plant Restrictions | Recommended Product Ratea | Addtional Commentsb | |

| % ai | Corn | Soybean | oz./A | ||

| Envive | Chlorimuron: 9.2% Flumioxazin: 29.2% Thifensulfuron: 2.9% |

Not labeled | Fall through spring and up to 3 days after planting | 2.5 to 5.3 | Apply to 3” or smaller wild garlic plants. Tank mixes with glyphosate and/or 2,4-D are strongly encouraged for increased efficacy |

| Synchrony XP | Chlorimuron: 21.5% Thifensulfuron: 6.9% |

Not labeled | 45 days preplant to just prior to soybean emergence | 0.375 to 0.75 with glyphosate 1 to 3 with 2,4-D |

Apply to 3” or smaller wild garlic plants. Addition of 0.5 lb ai 2,4-D required for complete control of wild garlic |

| Canopy EX | Chlorimuron: 22.7% Tribenuron: 6.8% |

Not labeled | 1.1-2.2 oz: Fall to 7 days before plantings 2.3-3.3 oz: Fall to 14 days before planting |

1.1 to 3.3 | Apply to 3-6” wild garlic plants. Addition of 0.5 lb ai 2,4-D required for complete control of wild garlic |

| Harmony SG | Thifensulfuron: 50% | Up to crop emergence | Up to crop emergence | 0.75 to 0.9 | Apply to actively growing wild garlic plants that are less than 12” tall with at least 2-4” of new growth |

| Harmony Extra SG | Thifensulfuron: 33.33% Tribenuron: 16.67% |

At least 7 days prior to planting | At least 7 days prior to planting | 0.75 to 0.9 | Apply to actively growing wild garlic plants that are less than 12” tall with at least 2-4” of new growth |

| aThifensulfuron an chlorimuron containing products are sensitive to soil pH, please refer to label for soil pH restrictions and application rates. bBurndown programs containing 0.5 lb ai 2,4-D must be applied at least 7 days prior to soybean planting. *Table contents derived from herbicide labels. Free herbicide labels can be accessed online at <http://www.cdms.net> or <http://www.greenbook.net>. |

|||||

![]()

Will Winter Annual Weeds Be An Issue This Year? – (Travis Legleiter and Bill Johnson)

Summer annual and herbicide-resistant weeds often overshadow winter annual weeds when producers formulate weed management strategies. With the unusually early spring and mild winter, winter annuals weed growth is proceeding at a rapid pace and they will be more troublesome this year as compared to past years especially in no-till soybean acres. As I have driven around the state over the last couple of weeks I have noticed an increase in the amount of winter annuals showing up in corn stubble and can only assume these acres will be planted to no-till soybeans. The amount of time between now and herbicide burndown applications and subsequent soybean planting in those fields is dependent on the weather, but no doubt at least a couple of weeks away. If the weather stays warm and dry, then burndown applications and planting will start relatively early on the calendar and should not be adversely affected by these winter annual weeds. Although if the weather turns cold and wet, keeping sprayers and planters out of the field, then the already heavy winter weed pressures will increase and become much more difficult to control. Increased winter annual infestations will slow soil drying, further delay planting, cause mechanical planting interference, and are harder to control with herbicide burndown applications. As well as fields with prolonged infestations of henbit and purple deadnettle can be at risk of high soybean cyst nematode populations.

Winter Annual Weed Burndown Applications

Some of the common winter annual weeds encountered in Indiana are henbit, chickweed, purple deadnettle, shepherd’s purse, and field pennycress. These common weeds, while fully capable being troublesome for the reasons mentioned above, are typically not considered to be hard to control weeds. A burndown containing a non-selective herbicide such as glyphosate (Roundup) plus either 2,4-D, saflufenacil (Sharpen, Verdict, Optill, and Optill PRO), or chlorimuron (Classic, Synchrony XP), will effectively control these weeds when applied at an appropriate time. Other burndown programs to consider are those that would replace glyphosate with Liberty or paraquat. The use of these programs will reduce selection pressure for glyphosate-resistant weeds. However it is important to use Liberty and gramoxone properly, that is, add the appropriate tankmix partners to ensure complete control of winter annual weeds.

Purple Deadnettle

Burndown applications are most efficient when made to young actively growing weeds. The likelihood of making soybean burndown applications to young winter annuals this spring is unrealistic as many are already flowering, but a number of practices can be used to assure that a burndown application is effective. Producers may consider making applications to relatively less mature weeds a few weeks prior to soybean planting. This will also allow time for dense mats of winter annual weeds to breakdown resulting in higher soil temps at planting as well as less mechanical planter interference. If choosing to make early burndown applications, producers should also include a residual herbicide to keep the field clean of weeds up to and through soybean planting. Those choosing to wait until just prior to soybean planting to make burndown applications should consider using increased herbicide rates to assure an effective kill of mature winter annuals.

Troublesome Winter Annual Weeds

Two winter annual weeds that are much more troublesome to control and are already showing up as prevalent weeds in Indiana this spring are wild garlic (which is actually a perennial weed) and marestail. Producers encountering these two weed species need to consider management strategies to control populations as early as possible as both species can be difficult to control in advanced plant growth stages.

Wild Garlic has become much more prevalent in agronomic fields this year especially in southern Indiana. Its hollow leaves, underground bulblets, and garlic to onion odor can help identify wild garlic. This weed is not effectively controlled by typical burndown herbicides mentioned above. Wild garlic can be controlled with a thifensulfuron or chlorimuron-containing product that is applied to plants that are less that 12” tall. Further details of wild garlic biology and control will be covered in a near future article.

Marestail will emerge in both the fall and the spring as a low growing rosette and bolt from early spring to summer. Once in the bolting stage and taller than a few inches, marestail is very difficult to control with herbicide applications. Plants that emerged last fall are undoubtedly already beginning to bolt and will be beyond that ideal application stage when soybean burndown applications begin. Producers should consider making early burndown applications to fields infested with marestail as well as including a residual herbicide at a full rate to reduce the amount of marestail emergence prior to and after soybean planting. For more information refer to the “Control of Marestail in No-till Soybean” publication released in collaboration by Ohio State and Purdue Universities. The following link will provide the PDF version of this publication:

<http://agcrops.osu.edu/specialists/weeds/marestail/marestailfact09_000.pdf/at_download/file>.

Summary

While much is to be seen between now and soybean planting, producers need to be aware that winter annual weed control may be more difficult than in past years because of the mild winter and recent warm temperatures. Strategies such as early burndown applications, increased herbicide rates, and the use of residual herbicides need to be considered in order to avoid planting delays and inference that can be caused by winter annual weeds. Producers with a history of SCN infestations also need to be aware of the harboring abilities of certain winter annual weed species. (Refer to Purdue publication WS-36 for more information on winter annuals and soybean cyst nematodes)

Soybean Growers and Consultants: Get Free Access to a Wealth of Crop Management Information Courtesy of the Soybean Checkoff - (Kiersten Wise)

As part of its tech transfer efforts, the United Soybean Board purchased 500 one-year subscriptions to the Plant Management Network (PMN) for soybean growers and the consultants who work for them. These subscriptions are available on a first-come, first-serve basis and are intended for first-time subscribers.

This subscription includes access to PMN’s entire collection of “Focus on Soybeans”

webcasts. More than 50 soybean webcasts have been produced to date, and they feature actionable crop management information from experts who work in the field. PMN subscriptions also include access to nearly 8,000 fungicide, nematicide, insecticide, and biological control trials; more than 1,000 applied crop management research articles; nearly 3,000 crop management news articles; about 5,000 images; tens of thousands of extension documents, and other information useful for growers and consultants. All of this is located through in one central website and searchable by keyword.

You can sign up for a free one-year subscription to all the Plant Management Network’s content through the signup form at the following short link: <http://bit.ly/GFDCzj>. Those who fill out the form will be allowed access to the site through a username and password of their choosing.

Once subscribed, users will receive article alerts once a month in the form of PMN’s Update newsletter. Subscriber-only content can be accessed through the username and password.

Only 500 subscriptions are available, so readers are encouraged to sign up for their free username and password as soon as possible. View PMN’s entire collection of soybean-inclusive resources at <http://www.plantmanagementnetwork.org/subscriptions/details/soybean.asp>.

Nitrogen Management Guidelines for Indiana - (Jim Camberato1, RL (Bob) Nielsen , Eric Miller, & Brad Joern)

6-YEAR SUMMARY OF CORN RESPONSE TO NITROGEN FERTILIZER

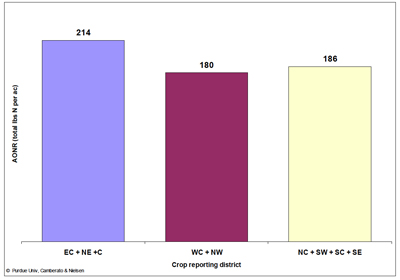

Results from field trials conducted around the state with efficient methods and timings of N fertilizer application suggest that the average Agronomic Optimum N Rate (AONR) for corn following soybean (corn/soy) varies by region or soil type. The estimated AONR for fine textured soils in westcentral and northwest Indiana is 180 lbs N / ac. The AONR for fine textured soils in northeast, eastcentral, and central Indiana is approximately 214 lbs N / ac. The AONR for the remainder of the state (NC, SW, SC, and SE) is approximately 186 lbs N / ac. At the five Purdue locations where we conducted paired trials of corn/soy and corn following corn (corn/corn) in 2007-2010, the average AONR for corn/corn was 44 lbs greater than for corn/soy while average corn/corn yields were 18 bu/ac less than the corn/soy yields.

Based on $0.50/lb N and $6.00/bu corn, the average Economic Optimum N Rate (EONR) for corn following soybean was 169, 198, and 173 lbs N / ac for WC+NW, NE+EC+C, and the remainder of the state, respectively. The EONR values for other combinations of N cost and grain price are listed in Tables 1-3. If you want to determine EONR for other N and grain prices, use the on-line N calculator for Indiana2 at this website: <http://extension.agron.iastate.edu/soilfertility/nrate.aspx>.

Nitrogen fertilizer costs remain volatile but continue to be one of the most expensive variable costs for corn. Applying “more than enough N” is no longer cheap “insurance” as it once was many years ago. Applying “more than enough N” is also not environmentally friendly. High N fertilizer costs and environmental impacts should encourage growers to critically evaluate their N fertility program, including application rate, fertilizer material, and timing.

Nitrogen rate recommendations for a given field were traditionally linked to its historical yield levels3. For corn/soybean, the traditional rule of thumb was an N rate equal to about 1 lb of N per bushel of expected yield. For corn following either corn or wheat, the recommendation was equal to about 1.2 lbs. of N per bushel.

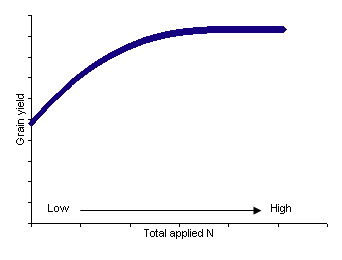

Graphic

These rules of thumb infer that the more N you apply, the more grain you harvest. Actually, yield response to N is usually not a straight-line relationship. In reality, the first pounds of applied N typically return the greatest number of bushels and the last pounds of applied N typically return the fewest number of bushels (figure to right). At some level of N, grain yield stops increasing with more N. Consequently, applying more N than the crop can use is dollar wasteful and environmentally distasteful.

Throughout the Midwest, most land-grant universities have moved away from yield-based N rate recommendations toward data- driven recommendations that are sensitive to N and grain prices4. This “new” approach to N rates links documented yield responses to N with the relative economics of grain price and N cost.

A couple of new terms or acronyms have developed from this approach. The term “Agronomic Optimum N Rate” or AONR defines the N rate that will produce maximum grain yield, regardless of cost. The term “Economic Optimum N Rate” or EONR defines the N rate that will result in the maximum dollar return to N. The EONR is usually less than the AONR, will usually decrease as N prices increase, will usually increase as grain prices increase, or may remain the same if the ratio between nitrogen cost and grain price (N:G) remains the same.

The “new” approach requires yield data from numerous field trials documenting corn yield responses to N fertilizer rates across a range of growing conditions. We began our current N rate trials in 2006. To date, 175 field-scale trials have been conducted around the state. About 58% of them have been with rotation corn and the rest primarily continuous corn. Over 60% of the trials have been on-farm research trials with farmers and the remainder has been trials at Purdue research centers around the state5.

The N rate treatments have ranged from nothing but starter N to as much as 286 lbs/ac applied N. Most of the trials used sidedress liquid 28% UAN simply to facilitate trial logistics. Similar results would be expected from late pre-plant or sidedress anhydrous, but not necessarily from early pre-plant anhydrous or 28% or fall anhydrous. Most of the trials were conducted on fine-textured soils: silt loams, silty clay loams, and the like. All of the trials have been field-scale; meaning that the individual N rate “plots” are usually field length by some multiple of the combine header width. Most of the trials have been harvested with the aid of GPS-enabled yield monitors.

Regional and Soil Differences in Optimum N Rate

Nitrogen used by the corn crop originates from soil organic matter and crop residues as well as from applied fertilizer. Some soils provide as little as 25% of the crop N requirement, the remainder coming from fertilizer N. Other soils provide in excess of 50% of the crop N demand, with a lesser amount needed from applied N. The N supply and N loss potential of a soil are related to soil properties and, of course, soils vary geographically around the state. In general higher organic matter and better drained soils provide more N to the crop and retain more fertilizer N than lower organic matter, more poorly drained soils. As we conduct more and more trials, we are identifying regional differences in AONR (Fig. 1) that make sense as we consider the soils in those regions. Our current research suggests that poorly-drained fine textured soils in northeast, eastcentral, and central Indiana require about 214 lb N/ac to optimize yield of corn/soy, whereas the AONR for better-drained fine textured soils in westcentral and northwest Indiana is about 180 lbs N/ac. These results were obtained with efficient fertilizer application methods and timings. The EONR is less than the AONR, based on the relative cost of N and value of grain. Economically optimum N rates can be found in Tables 1 - 3.

Figure 1. Regional differences for agronomically optimum N rate (AONR) based on 150 trials with corn following soybean to date since 2006. Note: Few of our trials since 2006 have involved sandy, well-drained soils

| Table 1. Range of economic optimum N rate (EONR) values (lbs/ac applied N) for corn following soybean as influenced by nitrogen cost per lb. N (Talbe 4) and grain price per bushel based on yield response data summarized over central, eastcentral, and northeast Indiana. The average agronommic optimum N rate for these regions of Indiana is estimated to be 214 lbs N/ac. | |||||||

| N Cost | Grain Price | ||||||

| $3.00 | $4.00 | $5.00 | $6.00 | $7.00 | $8.00 | $9.00 | |

| $0.20 | 201 | 204 | 206 | 208 | 209 | 209 | 210 |

| $0.30 | 194 | 199 | 202 | 204 | 206 | 207 | 208 |

| $0.40 | 187 | 194 | 198 | 201 | 203 | 204 | 205 |

| $0.50 | 181 | 189 | 194 | 198 | 200 | 202 | 203 |

| $0.60 | 174 | 184 | 190 | 194 | 197 | 199 | 201 |

| $0.70 | 167 | 179 | 186 | 191 | 194 | 197 | 199 |

| $0.80 | 160 | 164 | 182 | 187 | 191 | 194 | 196 |

| $0.90 | 154 | 169 | 178 | 184 | 188 | 192 | 194 |

| $1.00 | 147 | 164 | 174 | 181 | 185 | 189 | 192 |

| Based on field research conducted throughout Indiana 2006-2011. These rates assume N management practices that minimize the risk of N loss prior to plant uptake. | |||||||

| Table 2. Range of EONR values (lbs/ac applied N) for corn following soybean as influenced by nitrogen cost per lab. N (Table 4) and grain price per bushel based on yield response data summarized over westcentral and northwest Indiana. The average agronomic optimum N rate for these regions of Indiana is estimated to be 180 lbs N/ac. | |||||||

| N Cost | Grain Price | ||||||

| $3.00 | $4.00 | $5.00 | $6.00 | $7.00 | $8.00 | $9.00 | |

| $0.20 | 171 | 173 | 175 | 176 | 176 | 177 | 177 |

| $0.30 | 167 | 170 | 172 | 173 | 174 | 175 | 176 |

| $0.40 | 162 | 167 | 169 | 171 | 172 | 173 | 174 |

| $0.50 | 157 | 163 | 167 | 169 | 171 | 172 | 173 |

| $0.60 | 153 | 160 | 164 | 167 | 169 | 170 | 171 |

| $0.70 | 148 | 156 | 161 | 164 | 167 | 168 | 170 |

| $0.80 | 144 | 153 | 158 | 162 | 165 | 167 | 168 |

| $0.90 | 139 | 150 | 156 | 160 | 163 | 165 | 167 |

| $1.00 | 135 | 146 | 143 | 157 | 161 | 163 | 165 |

| Based on field research conducted throughout Indiana 2006-2011. These rates assume N management practices that minimize the risk of N loss prior to plant uptake. | |||||||

| Table 3. Range of EONR values (lbs/ac applied N) for corn following soybean as influenced by nitrogen cost per lb. N (Table 4) and grain price per bushel based on yield response data summarized over northcentral, southwest, southcentra, and southeast Indiana. The average agronomic optimum N rate for these regions of Indiana is estimated to be 186 lbs N/ac. | |||||||

| N Cost | Grain Price | ||||||

| $3.00 | $4.00 | $5.00 | $6.00 | $7.00 | $8.00 | $9.00 | |

| $0.20 | 175 | 178 | 180 | 181 | 182 | 182 | 183 |

| $0.30 | 170 | 174 | 176 | 178 | 179 | 180 | 181 |

| $0.40 | 164 | 170 | 173 | 175 | 177 | 178 | 179 |

| $0.50 | 159 | 166 | 170 | 173 | 175 | 176 | 177 |

| $0.60 | 154 | 162 | 167 | 170 | 172 | 174 | 175 |

| $0.70 | 148 | 158 | 163 | 167 | 170 | 172 | 174 |

| $0.80 | 143 | 154 | 160 | 164 | 168 | 170 | 172 |

| $0.90 | 137 | 149 | 157 | 162 | 165 | 168 | 170 |

| $1.00 | 132 | 145 | 154 | 159 | 163 | 166 | 168 |

| Based on field research conducted throughout Indiana 2006-2011. These rates assume N management practices that minimize the risk of N loss prior to plant uptake. | |||||||

| Table 4. Cost per lb. N for three common fertilizer sources of N at varying costs per ton of product. | |||||

| Anhydrous | N cost/lb | 28% UAN | N cost/lb | Urea | N cost/lb |

| $300 | $0.18 | $100 | $0.18 | $200 | $0.22 |

| $350 | $0.21 | $125 | $0.22 | $250 | $0.27 |

| $400 | $0.24 | $150 | $0.27 | $300 | $0.33 |

| $450 | $0.27 | $175 | $0.31 | $350 | $0.38 |

| $500 | $0.30 | $200 | $0.36 | $400 | $0.43 |

| $550 | $0.34 | $225 | $0.40 | $450 | $0.49 |

| $600 | $0.37 | $250 | $0.45 | $500 | $0.54 |

| $650 | $0.40 | $2.75 | $0.49 | $550 | $0.60 |

| $700 | $0.43 | $300 | $0.54 | $600 | $0.65 |

| $750 | $0.46 | $325 | $0.58 | $650 | $0.71 |

| $800 | $0.49 | $350 | $0.63 | $700 | $0.76 |

| $850 | $0.52 | $375 | $0.67 | $750 | $0.82 |

| $900 | $0.55 | $400 | $0.71 | $800 | $0.87 |

| $950 | $0.58 | $425 | $0.76 | $850 | $0.92 |

| $1000 | $0.61 | $450 | $0.80 | $900 | $0.98 |

More field research is needed in several areas of Indiana and on coarse textured soils to determine whether other regional and soil specific recommendations are warranted. Please consider collaborating with us in conducting on-farm research N rate trials (see pg. 10 for more information).

More Discussion on N Management

Although we report a single AONR for a region, specific AONR values can vary from field to field and from year to year for a single field. For example, the optimum N rate for our research site near West Lafayette was 165, 130, 186, 182, 186, and 179 from 2006-2011, respectively. This variation in optimum N rate is not particularly surprising since we’ve always known the difficulty of predicting soil N supply, fertilizer N loss, and growing season weather. Weather influences both soil N supply and fertilizer N efficiency. Crop health, N uptake, and N use efficiency are also weather- and soil- dependent.

Soil or fertilizer N lost to leaching, denitrification, or volatilization is N no longer available to the plant. Anhydrous ammonia is the least risky of the N sources because it is the slowest to convert to the nitrate form that is susceptible to leaching or denitrification losses. Urea-containing fertilizers should be incorporated to eliminate volatilization losses or a urease inhibitor can be used to delay the initial conversion of urea to ammonia (reducing the risk of volatilization loss). Nitrification inhibitors can be used with anhydrous, urea, or liquid N to further delay the conversion of ammonium to nitrate. Finally, sidedressing N will minimize the “window of opportunity” for N loss prior to plant uptake6. Practices such as fall-applied or early-spring applied N or surface-applied urea will require higher N rates than we recommend to attain optimum yield.

Even if you take steps to minimize the risk of N loss, predicting the optimum N rate for a particular field in a particular year remains a challenge. Several tools exist that may improve N management. These include: the Pre-Sidedress Nitrate Test7 which can be used to estimate soil N supply in manured fields or soils with very high organic matter content, a chlorophyll meter8 or active sensor in conjunction with a high-N reference strip which can be utilized during the growing season to evaluate crop N status, and the end-of-season stalk nitrate test9 which can serve as a “report card” to determine whether N was over- or under-applied.

The bottom line on N use in corn is that we’re dealing with a biological system that interacts with everything under the sun, including the sun. We cannot accurately predict the weather. We cannot accurately predict soil N supply throughout the year. Yet, we cannot afford (financially or environmentally) to simply apply “more than enough”. We can minimize the risk of fertilizer N loss by understanding the processes and matching N source with placement and timing. We can develop average N rate recommendations that will work in “average” years. We can attempt to fine-tune those recommendations with tests, models, optical sensors, or simply educated guesses.

We Are Looking for On-Farm Trial Cooperators

Our long-term objective is to develop more region- or soil-specific N rate guidelines. Conducting N rate trials on farmer’s fields is the best way for us to expand our efforts and increase the database for making regional recommendations. The general protocol for such trials is to apply strips of six N rates (for example, 70-110-150-190-230 lbs/ac N), repeated no fewer than 2 times across a field. Size of individual plots (a single N rate strip) can be length of field by some multiple of combine header width. Use of combine yield monitors is strongly encouraged primarily because they greatly reduce the harvesting logistics of such a trial. The general protocol for such a trial can be downloaded from the Web at <http://www.agry.purdue.edu/ext/ofr/protocols.html>.

If you are interested in conducting on-farm N rate trials, contact Jim Camberato (765-496-9338 or jcambera@purdue.edu) or Bob Nielsen (765-494-4802 or rnielsen@purdue.edu). We will work with you to come up with the best compromise between our desires for statistical soundness and your desire for logistical simplicity.

__________________

1 For more information, contact Jim Camberato (765-496-9338, jcambera@purdue.edu) or Bob Nielsen (765-494-4802, rnielsen@purdue.edu).

2 As of 3/30/12, the on-line N calculator was not yet updated with our 2011 response data.

3 A Historical Perspective on Nitrogen Fertilizer Rate Recommendations for Corn in Indiana (1953-2011). On-line at <http://www.extension.purdue.edu/extmedia/AY/AY-335-W.pdf> [URL]

4 Concepts and Rationale for Regional Nitrogen Rate Guidelines for Corn (PM-2015). On-line at <http://www.extension.iastate.edu/Publications/PM2015.pdf> [URL accessed Mar 2012].

5 We gratefully acknowledge the support provided for these trials by the Indiana Corn Marketing Council, Pioneer Hi-Bred Int’l and LG Seeds (seed contribution for Purdue trial sites), Beck’s Hybrids (additional trial data), A&L Great Lakes Labs (discounted analysis costs), individual farmers and crop consultants, Purdue Univ. Office of Ag Research Programs, and all of the Purdue Ag Center staff.

6 N Loss Mechanisms and Nitrogen Use Efficiency. Handout for 2006 Purdue Nitrogen Management Workshops. <http://www.agry.purdue.edu/ext/pubs/2006NLossMechanisms.pdf>. [URL accessed Mar 2012]

7 The Presidedress Soil Nitrate Test for Improving N Management in Corn. Purdue Extension publication AY-314-W, <http://www.agry.purdue.edu/ext/pubs/AY-314-W.pdf>. [URL accessed Mar 2012]

8 Determining Nitrogen Fertilizer Sidedress Application Needs in Corn Using a Chlorophyll Meter. Purdue Extension publication AY-317-W, <http://www.agry.purdue.edu/ext/pubs/AY-317-W.pdf> [URL accessed Mar 2012].

9 Cornstalk Testing to Evaluate the Nitrogen Status of Mature Corn. Purdue Extension publication AY-322-W, <http://www.agry.purdue.edu/ext/pubs/AY-322-W.pdf>. [URL accessed Mar 2012]

![]()

Seeding Depth Considerations for Corn – (Bob Nielsen)

Choice of seeding depth for corn is often paid scant attention by growers during the rush of planting their crop. Human nature being what it is, we tend to simply leave the planter’s depth control setting at the same position as in previous years. Indeed, many agronomists agree that a seeding depth of 1.5 to 2 inches is a fairly all-purpose range that works well in most situations. However, certain conditions merit consideration of changing seeding depth, the most common of which is soil moisture at seed depth.

Adequate soil moisture at seed depth (not too wet, not too dry) helps ensure rapid germination of the seed. Equally important is the spatial uniformity of adequate soil moisture at seed depth because that influences the uniformity of germination and subsequent emergence of the crop. The importance of the adequacy of soil moisture at seed depth is highlighted by the fact that imbibition of moisture by the newly planted seed occurs with the first 24 to 48 hours after planting.

Many growers have taken advantage of the unusually warm temperatures and minimal rainfall in recent weeks to complete their pre-plant tillage operations, herbicide applications, and nitrogen fertilizer applications. The completion of those activities certainly lends optimism that corn planting in 2012 will proceed at a rapid pace over the coming weeks if the weather continues to cooperate.

However, “cooperation” of the weather includes the absence of any significant rainfall that would delay planting. Therein lies the challenge this year in choosing the proper seeding depth because soil moisture near the surface is already borderline adequate for seed germination in some fields. Planting corn at the usual 1.5 to 2 inch seeding depth may place seed into soil too dry for germination or (even worse) into soil that is unevenly moist that will result in uneven germination and emergence.

If rainfall remains a scarce commodity over the coming weeks, growers should assess soil moisture at seed depth in every field they plant. There will be situations where a 2-inch seeding depth does not provide uniformly adequate soil moisture. There will be situations where growers should place seed deeper to minimize the risks of uneven germination.

Remember This: Corn has the physiological capability of emerging from depths far greater than that which today’s planters can place seed because of the innate ability of the seedling mesocotyl to elongate during the emergence process.

Soils in some fields are prone to developing dense surface crusts following intense rainfall events that can interfere with seedling emergence and result in seedlings leafing out underground. Growers naturally hesitate to plant too deeply in these soils because of this risk. My opinion is that the consequence of surface crusting is mostly influenced by the timing of the development of the crust relative to the timing of the emergence process and less so by the depth of seeding. In other words, a dense surface crust can impede penetration of the seedling coleopile whether the seed was planted 1.5 inches deep or 3 inches deep if the crust develops shortly after planting.

Field to field variability for adequacy of seed depth soil moisture may be dramatic this year. The risk/benefit of deep seed placement is influenced by the depth where adequate soil moisture is spatially uniform, soil temperature at seed depth, and the 6- to 10-day forecast for rainfall and temperature. A combination of 1) adequate soil temperature today, 2) inadequate or variable soil moisture at 2 inches, and 3) little to no rainfall expected in the next week or two represents a planting situation that calls for choosing a seed depth deeper than 2 inches.

Opinion: How deep is too deep for planting corn? Probably deeper than what your planter can plant.

Related Reading

Nielsen, RL (Bob). 2010. Germination Events in Corn. Corny News Network, Purdue Univ. online at <http://www.kingcorn.org/news/timeless/GerminationEvents.html> [URL accessed Apr 2012].

Nielsen, RL (Bob). 2010. Requirements for Uniform Germination & Emergence of Corn. Corny News Network, Purdue Univ. online at <http://www.kingcorn.org/news/timeless/GermEmergReq.html> [URL accessed Apr 2012].

Nielsen, RL (Bob). 2010. The Emergence Process in Corn. Corny News Network, Purdue Univ. online at <http://www.kingcorn.org/news/timeless/Emergence.html> [URL accessed Apr 2012].

![]()

Check Stored Corn for Potential Problems – Spring 2012 – (Matt Roberts and Richard Stroshine, Agricultural and Biological Engineering)

For many Midwest farmers, the mild weather this past winter was a welcomed change from the normal. It has led to lower heating bills for homes and shops, and favorable road conditions for hauling last year’s crop to market. However, the lack of extended periods of freezing temperatures also created some unique storage challenges. One such challenge was finding enough cold days to adequately cool grain stored at moistures above 15% to prevent mold growth.

In recent weeks there have been reports surfacing about producers finding spoiled grain in their bins or higher than normal percentages of heat damaged kernels in corn they are selling. When storing corn over the winter, it is best to cool grain to near freezing temperatures and maintain the cold temperatures as long as possible into the spring. Corn that will be stored into summer months should be at 45 to 50°F in June as air temperatures climb higher. Depending on bin and fan sizes, a cooling front may move through a bin in a matter of days while in other situations it may take several weeks. For example it may take up to 200 hours for a cooling front to move through the bin if airflow is 0.1 cfm/bu and up to 80 hours if airflow is 0.25 cfm/bu. If corn is above 15.0% moisture, it would be best to market it soon or dry it below 15% as soon as possible. At the very least you should inspect the stored corn frequently. The higher the moisture, the less time before there is significant mold growth.

If a bin has not been properly cored and leveled it will be difficult to evenly cool the grain mass. Coring is a process of removing one or more truckloads of grain from a bin after it is filled. Coring a bin removes the accumulation of fine material that often builds up in the center (core) of the bin during the filling process. Even with state of the art grain spreaders, fines can accumulate in the core and must be removed. In a grain bin, air finds the path of least resistance. A buildup of fines fills the air pockets between kernels and increases air flow resistance. Some studies indicate that if a bin has 3% fine material the airflow in that region of the grain mass would be reduced by 40%. This simply means that if the core of a bin that has 3% fine material it will take longer (40% or more) to cool the core than the rest of the bin. After coring is completed, the the top of the grain mass should be leveled. The airflow resistance will be greater wherever the grain depth is greater and this will make it more difficult to get air to that portion of the grain mass.

You need to inspect your stored corn, searching for signs of mold growth. You should be checking your bins weekly as the outside air temperature increases. Prior to entering the bin turn the fan on and let it run for 5 to 10 minutes. This should push musty odors, which are indicative of mold growth, to the headspace of the bin . Be sure to lock-out and tag-out unloading equipment before entering the bin and let someone know you will be in the bin or, even better, ask them to accompany you and stand outside the bin while you enter. Once inside the bin, smell for mold and walk the surface of the bin looking for crusted grain. Regardless of what you see and smell, use a metal rod to probe the grain and search for hard spots. Be sure to check the core and edges of the bin where fines tend to accumulate. Even if the bin is equipped with temperature cables it is still important to physically check the bin. Grain is a very good insulator and temperature cables are only effective in detecting temperature increases within 2ft in any direction of the cable. This means a hot spot can grow to a large size before it is detected. You can also purchase a temperature probe and track and record grain temperatures at various locations in the bin so you can detect increases in temperature not caused by aeration. A less sophisticated approach is to insert a metal rod into the corn and leave it for 15 to 30 minutes. If the rod is warm when you quickly remove it from the grain mass, you probably have mold activity in your corn. If mold growth is found the best thing to do is immediately remove corn from the bin until all the moldy corn has been removed.

Insects are also more active at higher grain temperatures (above 55°F), so producers should also be looking for signs of insect activity such as Indian meal moth webbing in the headspace or insects near the center surface of the bin. Insects can survive from one year to the next in the fine material beneath perforated floors and then migrate into the grain mass after grain is added to the bin in the fall, so there may also be activity near the bottom of the bin. This would be more difficult to detect. Removing a small amount of corn with the unloading auger, which should draw corn from the bottom center of the bin, may reveal this type of insect activity. Using a grain probe to obtain a sample from beneath the grain surface followed by careful inspection of the sample for insects should also be helpful.